|

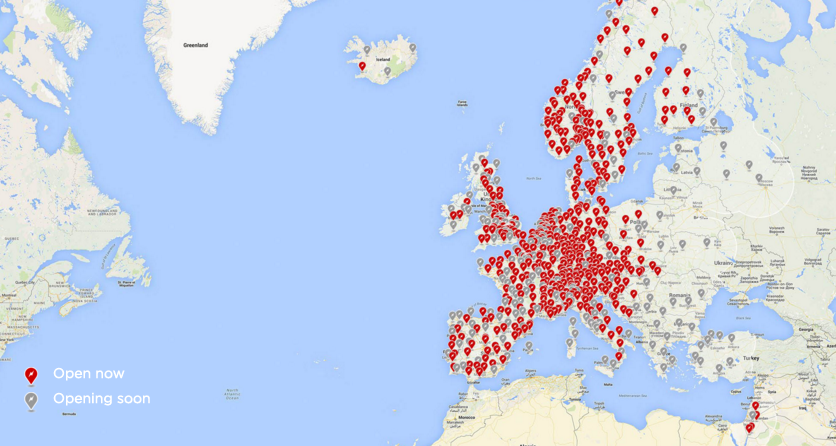

Since our last adventure most of our time has been spent trying to save the planet and the eco-systems we so dearly love and rely on. As every day passes the severity of the climate emergency we are in becomes more and more apparent. We dream of visiting the Amazon rainforest, but we fear that by the time we get there it might be gone! Every action has a carbon cost attached to it, which is making decisions very hard to make. Should we even continue our trip? Will we feel huge guilt by doing something so selfish when we should be fighting for the planet? How will we get to South America? Do we need to stop using Bee-bee because she runs on diesel? Is it feasible to use an electric 4x4 to overland the world? In this blog I’m going to focus on that last question. Is it feasible to use an electric vehicle to overland the world? The simple answer is yes. In 2017, our friends, Magdalena and Benedikt were the first to circle the Caspian Sea in an electric vehicle (Tesla Model S), from Switzerland to Central Asia and back via the Baltic countries. The “official” charging points finished in Croatia, forcing Magdalena and Benedikt to get “creative” adding a new dimension to an already tough overland trip. I had the pleasure of designing the vehicle graphics and interviewing them on The Overlanding Podcast. On the 7th of April 2019, The Plug Me In project finally reached Sydney from the UK after travelling for 1,119 days through 34 countries, covering 95,000km becoming the longest journey in an Electric Vehicle to date. So… It is possible, but... Is it greener to replace Bee-bee with an electric alternative? To calculate the carbon footprint of any vehicle is incredibly complex. The processes involved in getting raw minerals from the ground and made into a showroom ready vehicle are multifaceted and include many separate industries. Components have to be produced and often transported and then assembled. Every stage of the process requires energy and produces carbon, including the production of buildings and infrastructure (robots, phones, desks, etc). Once the vehicle has been built, the way it is used, how old it is and how well it has been maintained are all wildly erratic variables that affect the amount of carbon it produces. Luckily someone else has done most of the hard work for me. In his book “How Bad Are Bananas” – Mike Berners-Lee concludes that most new vehicles have a carbon footprint that equates to a monetary value. Berners-Lee suggests that a new vehicle will have a 720kg per £1000 that you spend on it. Unfortunately our vehicle isn’t new. Bee-bee is 26 years old and has a 3-Litre Turbo Diesel engine that has been well maintained. Typically, embodied emissions produced in the production of new cars equal the exhaust pipe emissions over the entire lifetime of the vehicle. Bee-bee is older than average. Berners-Lee deduces - “Generally speaking, it makes sense to keep your old car for as long as it is reliable, unless you are doing high mileage or the fuel consumption is ridiculously poor.” Essentially the longer you keep your vehicle the more the embodied emissions reduce per mile over time. On top of the Carbon produced by burning the fuel there is the carbon cost of getting the fuel out the ground, refining it and then shipping it around the world. Diesel engines are typically about 30% more efficient at turning fuel energy into vehicle movement. Unfortunately for us, each litre of Diesel has a slightly higher footprint (13 per cent) than petrol, but it produces a proportionately higher energy to compensate. Typically petrol is a cleaner option. Sadly diesel engines produce higher levels of microscopic particulates and nitrogen oxides and contribute massively to reductions in air quality that effect humans. These ultrafine particulates can penetrate deep into the lungs, causing irritation and can potentially trigger asthma attacks and cancer. According to Berners-Lee “Overall, it is hard to say which fuel wins as the environmental vehicle fuel”. What we do know is that both petrol and diesel are pretty terrible for the planet, with diesel being worse for humans. How does that compare with an electric vehicle? If the production of the vehicle produces about 50% of the total carbon footprint with exhaust pipe emissions making up the other half, does that mean that 50% of the total carbon footprint of an electrical vehicle is tied up in the production too? No, is the simply answer. Electric cars use lithium-ion batteries. The extraction of the exotic materials (lithium, cobalt, magnesium and nickel) used to produce those batteries creates hotspots in the vehicle manufacturing process. In a head-to-head comparison, electric vehicle production generates about 97% more carbon than a traditional combustion engine, with about 43% (the hotspot) of that being the battery. As technology advances these figures should reduce. Electric vehicles are charged by coal, gas and nuclear power stations, as well as some renewable sources, all of which have an associated carbon footprint. So that raises the question – how much of a carbon saving does an electric vehicle actually give you? Well thankfully, again, someone else has done the hard work for me. Volkswagen (who can definitely be trusted when it comes to telling the truth regarding emissions) carried out a like-for-like cradle to grave comparison between a pure electric e-Golf and a diesel-powered Golf TDI. Volkswagen concluded that “even in countries that are intensely reliant on coal-fired electricity, like China, a battery electric model will always pollute less CO2 than one with an internal combustion engine”. Even with the additional carbon produced during the production of the battery the typical saving is about 15%. This would be greatly increased if the electricity used for charging was sourced from renewables. That figure came as quite a surprise to me. I was expecting it to be a much higher saving. It is pretty much impossible to come to a definitive conclusion as to the carbon saving figure we would make by switching to an electric vehicle – we simply can’t compare like for like. It would be fair to say though that we wouldn’t be adding more carbon by switching, especially if that vehicle was second-hand. You only have to have a quick glance at the Electric Vehicle World Sales Database to realise the rate at which the sector is growing. As a result of the expanding electric vehicle market (and popularity of handheld devices), the demand for lithium is increasing exponentially. Between 2016 and 2018 Lithium doubled in price. Ironically, as the world clambers to replace fossil fuels with clean energy in an effort to clean up the planet, the consequences of extracting that much lithium is becoming a major issue in its own right. Toxic chemical leaks from Lithium mines have wreaked havoc with ecosystems and it’s predicting that, by 2050, the demand for the exotic metals essential for lithium-ion batteries may be in short supply. The lithium extraction process uses huge amounts of water, in Chile’s Salar de Atacama, mining activities consumed 65% of the region’s water. Lithium is not the only problematic metal used in producing batteries. Cobalt, unlike most metals, is classified as a toxic carcinogen and has been linked to cancer. It’s found in huge quantities across the whole of the Democratic Republic of Congo and central Africa and in recent years the price has quadrupled. These factors have resulted in unauthorised mines cashing in on the demand, resulting in unsafe and unethical methods of extraction, often using child labour, without the appropriate health and safety equipment and procedures. The final issue with lithium-ion batteries is what to do with them once they reach the end of their lifespan. They are incredibly difficult to recycle. Ironically when researching this blog post I discovered two companies, Voltra and Tembo, that make an electric 70 series Landcruiser… wait for it… to be used in mines that excavate coal. It is common knowledge that the world would be a much better place if fossil fuels were left in the ground. Where’s Alanis Morissette when you need her!? “Voltra provides underground mining fleets with the durability and toughness of the original 79 series Land cruiser, but with zero emissions, significantly reducing a mine’s carbon footprint”. Being an environmentally conscious overlander is hard work. Making the correct decisions to limit your own impact on the world is a minefield of complicated sums and moral dilemmas. Is there even a suitable vehicle that could replace Bee-bee? The market for off-road electric vehicles is currently slim. Telsa announced the CyberTruck last year. One part DeLorean, one part stealth bomber, it’s not the most attractive of vehicles and where would we put the rooftent? Elon Musk claims it’ll have a +500 Mile range, he also claimed it was bulletproof. At it’s big reveal, Telsa’s head of design, Franz vol Holzhausesn threw a metal ball at the windows to demonstrate how tough it was, embarrassingly the glass broke. With a price tag of +$60,000 for the all wheel drive tri-motor version and a release date of 2022 it’s highly unlikely to happen for us! The most likely contender to populate the electric overland market is the Rivian R1. With a +400 mile range and some smart design Rivian are aiming for a market they understand. The Rivian R1 will be available as a pick-up and 7 seater station-wagon, has a wading depth of nearly a metre, up to 750hp, advanced traction control, a low centre of gravity and an incredible 0-60 time of 3 seconds. With independent motors operating each wheel it can even perform 360 degree “tank turns”. Again, with a price tag of +$60,000 and a pre-order waiting list I think we can cross this one off our list. Some companies offer conversions for existing 4x4’s. For the traditionalist, Plower in Holland can build you an electric Land Rover Defender. In Germany Kreisel can build you a fully electric G-Class.

As all these vehicles are well out of our price range we find ourselves asking the question again - Is there a suitable vehicle, which could replace Bee-bee and appease our demand to see the world with as little impact on the planet as possible? Yes… a bicycle.

0 Comments

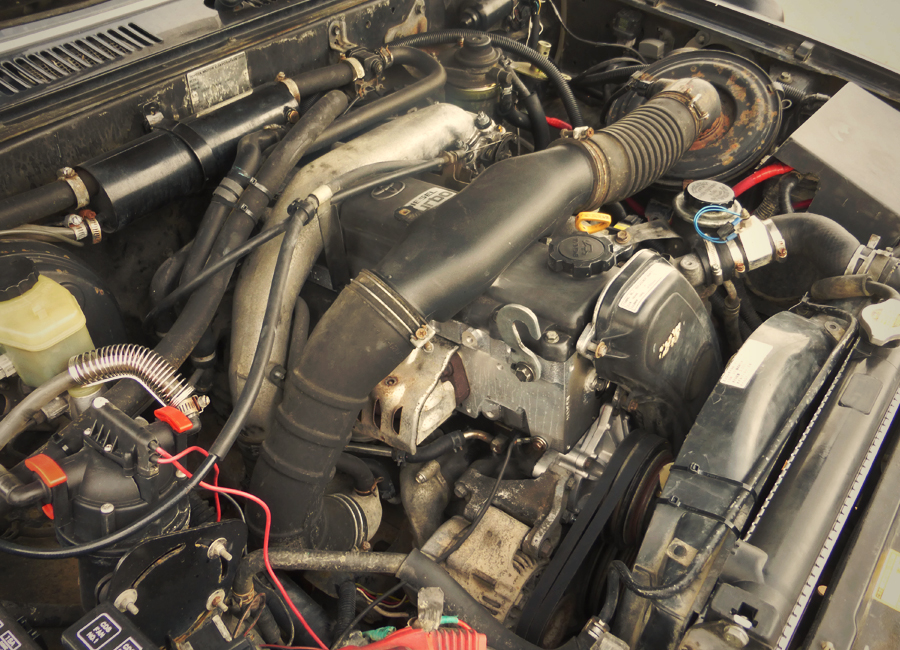

After a short hibernation period were about to head back out on the road. Bee-bee’s cracked cylinder head has been replaced and she is raring to go (we hope). Here’s a quick outline of the work she’s had done... New Cylinder Head

Water Pump

Radiator

Cam Belt, Glow Plugs and Fuel Injectors

Having racked up over 150 test kilometres I’m pretty convinced she’s running sweeter that she ever has. She starts on the button, no more black smoke and the temperature barely rises above 88°C. We took her (unloaded admittedly) on several long motorway climbs and up a steep 290 metre off-road climb without any problems at all. Fingers crossed.

What was that bang?

At first it seemed like Bee-bee had just overheated and popped the top off the expansion bottle. We let her cool down and refilled the radiator. We tried to start the car but got nothing but a ‘clunk’. Andy thought the starter motor might be jammed, we rocked Bee-bee backwards and forwards (for sympathy and to hopefully un-jam the starter motor). A turn of the key and she sprang back to life in a huge cloud of white smoke. It was at this point that Andy declared that we’d probably blown the cylinder head and that water had leaked into one of the cylinders which became ‘hydrolocked’. We sloped on cautiously towards the next town in a cloud of white smoke. Stuck in Kumluca

Frantically searching the Hilux Surf forum for advice on what he suspected, Andy declared he was “95% sure the Head gasket had blown”. Aside from a crash, this was one of the worst things that could happen to our car (mechanically and financially). We had 48 hours to get us and a broken car 301.43 miles (485.10 km) to the Port of Tasucu where a non-refundable ferry was due to take us to Cyprus. As with every tragedy there are the heroes and villains; our hero was Alim the hotel manager’s son who spoke English, understood our predicament and arranged for some tow truck people to come in the morning. The unfortunate villain was the waiter in the restaurant who informed me they didn’t serve alcohol. Tow Truck (Wheelin' and Dealin')

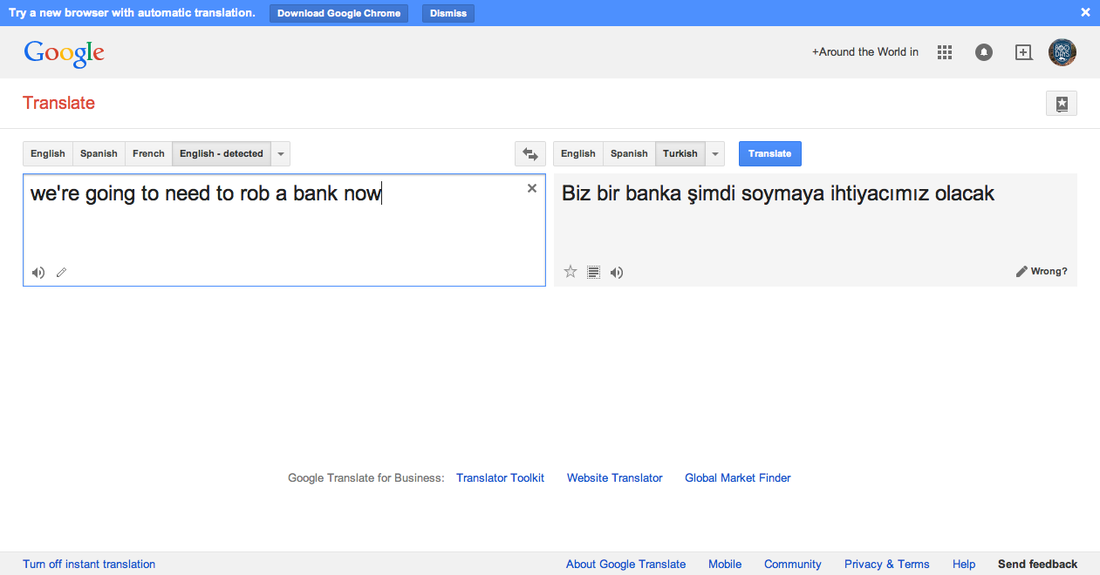

The final computer translation told them we were off to rob a bank. Ironically, when Alim took us to the cash point I sat in the back with a shotgun under my feet. I assume that was a normal item in a car here and he understood we were joking about the bank. I didn’t mention it. Tow Truck 1 - Ugel the Rally Driver

Tow Truck 2 - Mustafa the Redbull Racer

We spent about 2 hours in a smoky (but warm) station office with a Turkish soap opera on TV in the corner. A car of oily youths arrived with a few ‘new’ alternator options and scrambled about systematically until the truck roared into life again. Mustafa necked 2 cans of Redbull. We were off. We Drove All Night

17 Hours in Tasucu Port

We walked back into town (not daring to ask for a lift). During this time we must have set a local record for number of teas drank. We were exhausted and cold, we rooted at a friendly local café, ordering small dishes with lengthy interims to justify our temporary residence at their table. When it eventually went dark we bussed our way back to the Port but were stopped at the customs gate where we spent another hour dozing in chairs with bored customs officials in their office. Eventually they let us have access to Bee-bee (if we ran through the port and no one saw us). We popped the tent subtly, sandwiched between rows of lorries and lay down for an hour. All Aboard The Lady Su

Crossing the Cilician Sea

He beckoned us over to come up so we made our way through the ships corridors, stepping over piles of broken furniture and tools, up onto the ships bridge. Muhammed, the lone Captain, seemed to appreciate our company up on the bridge- he gave us bananas and told us that the boat had to be registered in Sierra Leone as it would never have passed strict Turkish health and safety regulations. Docking in Girne

Across Aphrodites' Island

The DiagnosisThe devastating news was what we expected; the cylinder head was cracked in two places. Bee-bee certainly picks her moments… The first time she broke down was in Russia when the alternator died and the battery ran flat leaving us stranded across a railway line!

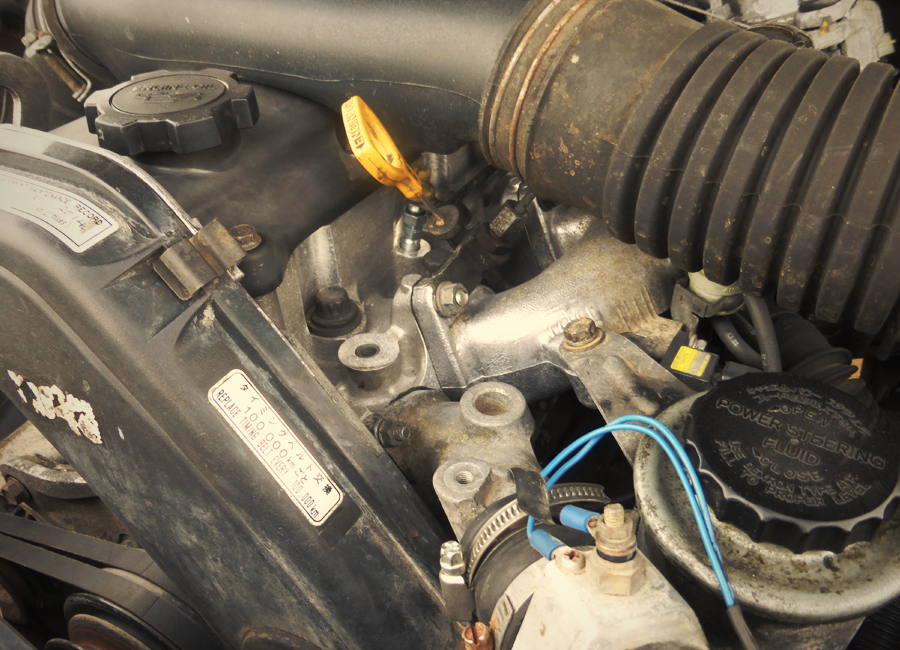

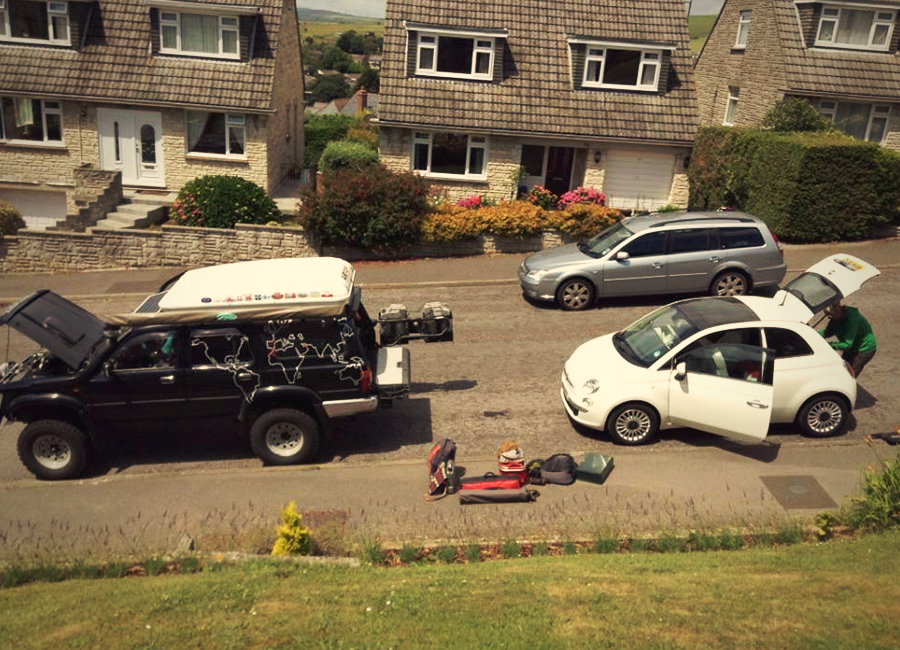

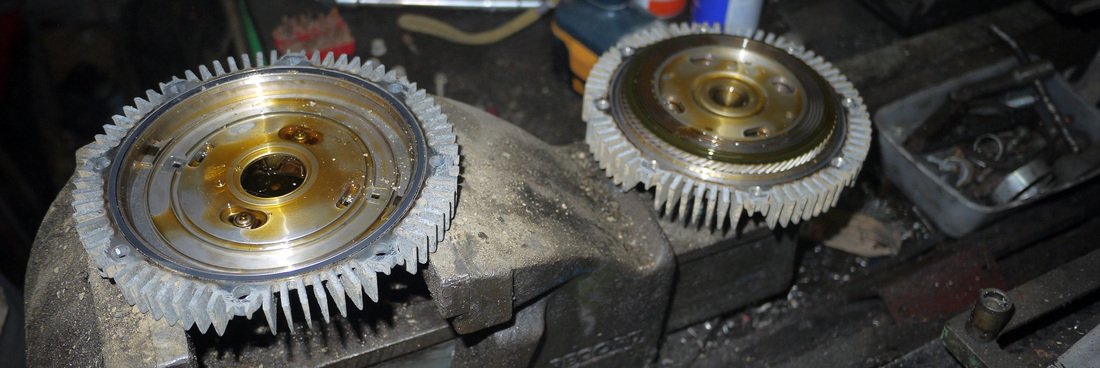

Last weekend she again threw her toys from the pram at the most opportune moment! On Saturday prior to leaving for a family camping trip she refused to start. The car was packed, the fridge was loaded, the batteries were charged, she turned over, but just refused to start. On closer inspection I noticed the glow-plug warm-up light wasn’t coming on either. After a few checks with the meter and a quick visit to the Hilux Surf Forum I diagnosed the problem as the Electronic Control Unit (ECU). Hopefully. It seems that it’s a common problem with at least two other people on the forum suffering the same fault this year. As it’s Bee-bee’s 20th birthday this year I’m wondering if Toyota have programmed a self-destruct sequence into the ECU! So with a little white hire car in place we headed off camping with my nieces while Bee-bee missed out on all the fun, sat inactive and sulking on the driveway. The trip was planned to not only spend time with family but to also road-test all our kit prior to setting off again. The ECU has now been sent to the highly recommended ECU-Doctor. With a car our age these kinds of parts are not available new anymore. Buying one from a broker is risky, so the best course of action is to get the ECU repaired and remapped. The ECU-Doctor can diagnose and confirm the suspected fault, repair it and offer a 12-month guarantee in the process. Let’s hope I’ve diagnosed it correctly and that he can work his magic on Bee-bee’s brain! Prior to our Truckin’ hell we’d made the decision to head straight back home; unfortunately we were 8000 miles away in Mongolia. In hindsight our departure from Mongolia was probably a little too hasty; a bit more Dakar Rally than Mongol Rally. Bad roads coupled with some wannabe Sébastien Loeb-esq driving damaged Bee-Bee’s rear axle. Luckily my daily under-car crawl exposed the hairline crack in the right-hand side upper trailing arm mount early on. The part that had cracked is essentially one of four main connections holding the entire rear axle in place. The discovery was an unnecessary blow – talk about kicking a man when he’s down! Due to the remoteness of our location we had no choice but to lash up the mount with a heavy-duty ratcheting cargo strap and hope for the best. I kept a close eye on it over the following 300 miles of bad road. It gradually got worse, by the time we arrived in Russia the mount had completely sheered off but luckily the pot-holed corrugated dust roads of Mongolia had been replaced by relatively smooth Russian tarmac. The ratchet strap was now holding everything tight in place. A weld job would mean we’d lose a valuable day’s driving and a complete axle replacement would mean we’d lose a good week. Given the situation and the need to be with my parents we re-evaluated our options and decided the temporary fix was secure enough to last the journey home; it did. Macgyver would be proud! On our return to the UK we started the process of getting Bee-Bee back into ‘adventure’ shape. A new axle was sourced from Jap 4x4 Parts and a visit to the Hilux Surf Forum secured a date with Tony the Hilux Surf oracle. Whilst the axle was off it made sense to replace anything that might have already taken a battering. A visit to Rough Trax secured a Super Pro polyurethane rear panhard rod & trailing arm bush kit, some new bump-stops, anti-roll bar bushes and a couple of front anti-roll bar link rods which had also taken a battering. The axle swap was fairly straightforward, especially with Tony’s knowledge. One area that could have been problematic was swapping the trailing arm bushes. Luckily Tony has access to a 25 tonne press and a lathe. The press ram was a little too large for the bushes so Tony hit the lathe and knocked up a couple of male and female adapters to fit either side of the bushes. With the press the old bushes popped out pretty easily and the new ones straight in. We had trouble undoing a couple of bolts, reminding me of the importance of Copaslip, nothing the reciprocating saw couldn’t deal with though. When replacing axles on 4x4 vehicles it is important to check the diff ratios are the same, if not you’ll have back wheels that’ll want to turn at a different speed to the front wheels making for a very interesting ride. On a Toyota this information can be found on the VIN plate in the engine bay. The axle code is four digits, ours is G294, this translates to a differential size of 8.0", final ratio of 4.1, and a 4 pinion set up. This website was very useful for translating the code. You can also double-check the ratio as Toyota colour code the end of the diff, double check the two axles are the same and you should be right! When fully loaded Bee-Bee has always had a bit of a saggy back end. Whilst we had the springs out we fitted a pair of spring assisters to help firm up the already upgraded springs. A couple of days in the workshop gave us a great opportunity to not only replace the axle but complete a few other jobs refining Bee-Bee’s status as number one adventure mobile. One modification we carried out was to remove the air-con unit and air-con radiator. This would improve access to the alternator and improve airflow through the main radiator as well as removing one of the three fan belts (less to go wrong and less to carry). The left over air-con electric radiator cooling fan is now acting as an emergency, manually operated cooling fan aimed at the main radiator. Whilst the main radiator and fan were all out we topped up the oil in the viscous fan. This modification is a very simple but effective one. The fan on these vehicles is of the viscous type. This means that is has an oil operated clutch in it. When the engine heats up, the oil changes consistency and the fan starts to grip more and turn faster. The oil in the fan can be replaced with a different consistency making it kick in slightly earlier, cooling the engine more effectively.

The mods to the cooling system now make a noticeable difference to Bee-Bee’s running temperature and we have the option of turning on the electric auxiliary fan when the temperature starts to rise too. If you want to read more about some of the other cooling mods we’ve made to deal with the extra weight, click here. Andy Last weekend, little Bee-Bee spat her dummy from the pram for the first time. I had spent the day clay pigeon shooting and boozing on the little island of Herm, on my return to Guernsey, Emma drove Bee-Bee into town to pick me up from the pub. When it was time to leave Emma went to start Bee-Bee and all we got was the dreaded solenoid click. By this time the days drink had caught up with me and I wasn’t on my top car fixing form.

The lights, windows, etc worked and so the batteries (our Surf is fitted with a winter kit which means it has two starter batteries for extra ummmph) were not completely flat. Although being a little drunk I still knew that this didn’t actually mean a thing, to start the car uses ALL the power and if the batteries had run down just a little they might not have had the kick to get the starter motor going. In my inebriated state I did the classic repeating myself thing, and constantly asked Emma if she had left the lights on. Luckily with the bonnet raised someone recognised the international symbol for ‘car help needed’ and offered a jump start (from a smug Range Rover owner no less). We rolled the car back and attached the jumper cables. Still the starter motor just clicked away. I tried knocking the starter motor with a hammer to try and get the solenoid to engage, I also tried rocking the car back and forth in gear a few times too. The Range Rover owner left and two minutes later someone else offered a jump start, again nothing helped. In the end trying to fix a car in the dark, wet (it was raining...I hadn’t pee’d myself) and whilst drunk seemed a little pointless and so we pushed her back into a car park space and got a taxi home. The next day with a clear head, daylight and a few tools we headed back down to the car. We initially tried turning the key in the hope that she might have magically fixed herself, but all we got was the dreaded click, click, click, click. A quick mooch under the bonnet revealed one of the two fan belts that run to the alternator had snapped. The Surf has a three belt system (one for the air con and two for the alternator/water pump) so that if one snaps, the remaining belts will still power the water pump so the car won’t over heat. The remaining belt that was running to the alternator was loose and more than likely turned the alternator but not enough to maintain a regular charge to the batteries. After a bit of tinkering and some butchering of some incredibly cheap jumper leads we managed to fire Bee-Bee up by jumping her off our Toyota MR2. I’m still a little confused why the Range Rover didn’t chuck out enough power to get her started whilst the little battery in the MR2 did the job fairly easily. Anyway she was running and we managed to get her home. I ordered a belt kit with the plan to change all three belts whilst I was at it from Rough Trax. Two days later the belts turned up, along with a new heavy duty set of 3m jumper cables. I also collected my multimeter from work, with the plan of testing the alternator, starter motor and batteries properly. I had Friday afternoon off work and decided to get busy on the belts. This was the first time I had worked on Bee-Bee properly and everything was going swimmingly, a few bolts were a bit awkward to reach but nothing out the ordinary...until! I got to the point where it was time to put the new belts on, the alternator was as loose as it would go on the adjustors but the belts seemed to by mm’s too short. I had no doubt that the belts weren’t correct as Rough Trax specializes in Hilux Surf’s. The only reason I could think of was that because the alternator had recently been replaced and that maybe the new one was not a stock Toyota part and the spacing was set-up slightly differently. Anyway after an hour of trying every trick in the trade to get them on I decided I had enough for one day as the light was dropping. Feeling very disheartened I hit up the Hilux Surf forum with the hope that someone else had encountered the same problem and that the answer was awaiting me in html format. No such luck. In bed that evening I had a bit of a brainwave; if I removed all the alternator bolts rather than just releasing the tension on it, then I could angle the alternator, hook the belts over and bolt it back in place with the belts on. In theory it seemed like a good idea. On Saturday morning I logged on to the forum again and posed the question, being slightly impatient I didn’t bother waiting for anyone to reply and decided to just crack on with it. The alternator is held in place with just two bolts; one acts as a pivot and attaches it to the engine whilst the other bolts it to the tension adjustment set-up. It was a bit of a squeeze to reach both of these but they came out without too much of a fight. The alternator on the other hand was well and truly wedged in place between both sides of the pivot bracket, with some seriously wiggling/prying it dropped out. Having the alternator loose meant that it was easy to hook the two fan belts over the pulley. When came the time to put the alternator back I was faced with yet another problem. The mount on the engine block where the alternator pivots has a shim in it that tightens up against the alternator to clamp it in place when you tighten the main alternator bolt. This shim was wedged in position, to the point where I wasn’t even sure it was supposed to move. The shim being wedged in place meant getting the alternator back in between the mounts was nigh on impossible. Again I went to the forum for help, and again being impatient I didn’t wait around for an answer. I popped to the hardware store and bought a nut, bolt and washer set-up with the idea of sandwiching the shim back in place by tightening the nut and bolt through it. It worked, with the shim back in the open position it gave me loads more room to play with and slipping the alternator back in with the belts on was a piece of cake. The second bolt was a little more annoying to get in but it went with a bit of persistence. After that everything went back together fairly straight forward. Once back together with the batteries in place I checked them with the meter and discovered they still had just under 12v in them. I tested the new jumper cables and she started first time, I checked the meter reading again and the batteries read at 14.3v so no problems with the alternator. I left it running for 10 minutes to build up some charge and switched her off and tried her again, she started first time. So what should have been a simple 30/40 minute job turned into about a 3 – 4 hour job. Once I had finished I checked back on the forum and discovered that a few people had commented on my post, most advised it was a bad idea and pretty much not possible. So despite all the problems and against the odds I was just happy that I managed to find a way to do it. Although in hindsight there may have been an easier way to do it by removing the water pump pulley and hooking the belts over. Anyway, it has been about 10 years since I have worked on any cars and if I had not been able to sort this it would have really knocked my confidence. One thing it has taught me is that improvising works but having the correct tools for the job really speeds up the process and lessons the stress. Andy |

Archives

July 2020

Categories

All

|

Proudly powered by Weebly

RSS Feed

RSS Feed